Kanban service for just in time supply

WAREHOUSE PROBLEMS?

FIND OUT HOW WE CAN REDUCE YOUR MANAGEMENT COSTS.

ASK FOR CATALOG NOW !

CONSULTING

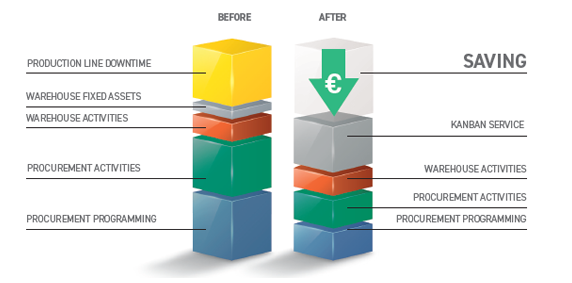

VIPA’s V-Lean system allows you to procure material more smoothly and optimise stock management, saving time and costs.

With the support of the V-Lean supply chain team, VIPA provides a consulting service for implementing the V-Lean Kanban system and consolidate the partnership between clients and suppliers.

By analysing the production process, VIPA helps you define the following parameters for achieving effective Kanban:

• AVERAGE ITEM CONSUMPTION PER TIME UNIT

• AVERAGE KANBAN STOCK COVERAGE

• SAFE STOCK LEVEL

• CONTAINER SIZE AND QUANTITY

SUPPLY

Vipa can provide various modular shelving systems with a number of shelves and columns designed based on the Kanban size and the client’s requirements.

Recoverable boxes available in various formats:

• with hopper front

• with or without a transparent door for easy use at the assembly benches

• with cover for products that need protection against dirt

• KLT

DATA MANAGEMENT

To inform VIPA about product consumption trends, the client’s operator must “download” the tag taken from the warehouse.

CLIENTS CAN MONITOR CONSUMPTION AUTONOMOUSLY BY ACCESSING VIPA’S WEB PORTAL.

THIS PORTAL ALLOWS CLIENTS TO CHECK THE MAIN MATERIAL CONSUMPTION INDICATORS, SHOWING:

• THE LIST OF KANBAN-MANAGED CODES, HIGHLIGHTING THE STATUS OF EACH CONTAINER

• STOCK/CONSUMED IN SALES ORDER WITH AN INDICATION OF THE DATE OF THE LAST WITHDRAWAL.

SOLUTIONS

V-SCAN

V-Lean Scan is a touchscreen barcode reader that works with a SIM card or in wi-fi mode.

It reads the barcode of the Kanban identifier and sends the data to VIPA’s IT system to create the recovery order.

V-BOX

V-Lean Box is a system that automatically reads the data via RFID.

Every Kanban container is fitted with a rewritable RFID tag that interacts via the V-Lean Box. The consumption-related data of the single material in the Kanban container is transferred automatically to our ERP system by positioning the container inside the RFID portal.

The RFID system helps unload the consumed containers, allowing the operator to transmit data more promptly, reducing possible errors.

V-EASY

V-Lean Easy is the ideal small industry solution that simplifies material sorting procedures.

The laser barcode scanner is lightweight and easy to use: configuration is carried out using a mobile phone (Android, Apple, Blackberry, or Windows mobile) connected via Bluetooth.

The barcode data scanned by the scanner is stored in the device (up to 20,000 codes) and transferred to the mobile phone, from which the order can be sent by email to VIPA practically, quickly and accurately: zero errors and the utmost simplicity.

DELIVERY & LEAD TIME

During the analysis, VIPA studies the configuration with the client to evaluate the various options:

• KANBAN IN THE CUSTOMER’S WAREHOUSE

• KANBAN IN THE DEPARTMENT WAREHOUSE

• KANBAN IN THE ASSEMBLY LINE

All this is required to define quantities and supply frequency and ensure optimal delivery dates.

Goods can be delivered at the client’s warehouse, the department warehouse or the assembly line. Deliveries can be managed by:

• VIPA’s carriers if the client is near one of our warehouses in Italy and outside Italy.

• Our trusted partners in Italy and outside Italy.

After careful analysis by our experts, the logistics specifications will be defined, including service Lead Times, empty container collection Cut Offs and delivery schedules.

The solutions are countless and agreed with the client.